Airotech Minerals

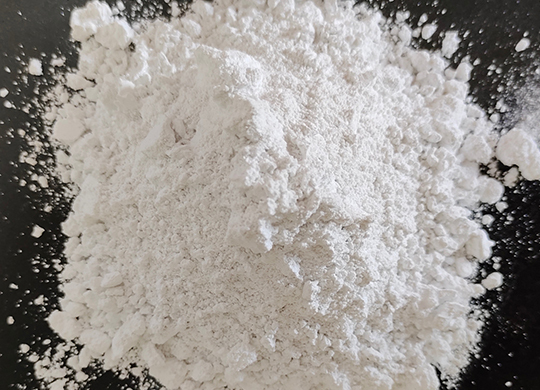

Precipitated calcium carbonate (PCC) is a unique substance generated from lime that has numerous industrial applications. PCC is created by hydrating high-calcium quicklime and then reacting it with carbon dioxide to form a slurry known as "milk-of-lime". The final product is exceptionally white and has a consistent, narrow particle size distribution. PCC is available in a variety of crystal morphologies and sizes, which can be customized to maximize performance in a specific application.

The main advantage of Precipitated Calcium Carbonate (PCC) is the ability to synthesize particles with a specified crystalline form that is much smaller, resulting in narrower and more defined granulometric distributions.

Send EnquiryTypical Chemical Analysis

| CaCo3 | 98 ± 1 |

| MgCO3 | 2+1 |

| Al-silicate | < 1% |

| Fe2O3 | < 0.1% |

| Moisture | 0.2% (Ex works) |

Typical Physical Analysis

| Sp.Gravity | 2.7 |

| Bulk Density | 950 gm/lit |

| Oil Absorption | 19% |

| PH of Sat Solution | 8.2 |

| Moisture | 0.2% (Ex works) |

| Particle Size | Average | Top Cut |

| Distribution | 3.0 M | 12 M |

Features

Less abrasion

Due to its regulated particle size and shape, PCC is less abrasive than other types of calcium carbonate. This feature makes it ideal for applications requiring abrasion resistance, such as paper manufacture.

Specific superior precipitated surfaces:

PCC can be manufactured to have various surface qualities depending on the manufacturing method. This customization enables specialized surfaces that can improve interactions with other materials in applications such as coatings, adhesives, and sealants

Narrower and more stable grain size distribution:

PCC's grain size distribution is often narrower and more stable than that of naturally occurring calcium carbonate. This consistency is advantageous in a variety of applications that require exact control over particle size.

Higher chemical purity:

PCC is often made using controlled chemical precipitation techniques, yielding a product with high chemical purity. This purity is critical for applications that demand high-quality standards, such as pharmaceuticals, food additives, and cosmetics.

Smaller and more uniform particles:

PCC particles are smaller and more homogeneous than naturally occurring calcium carbonate. This property helps to increase dispersion in solutions and homogeneous distribution in solid matrices, resulting in better performance in applications such as plastics, paints, and rubber.

Applications

Use of PCC in the Paper Industry

PCC has established itself as a filler and coating pigment for high-quality paper products. PCC is usually manufactured in slurry form at satellite operations near paper mills. PCC improves the optical qualities and print characteristics of paper products, increases paper machine productivity, and can lower papermaking costs by replacing more expensive pulp fibre and optical brightening chemicals. With ever-growing quality objectives, paper brightness, and hence PCC, becomes an increasingly essential component.

Use of PCC in the PVC/ Plastic industry

PCC is widely used as a filler in PVC and other plastics. It helps to cut costs by substituting some of the more expensive resin materials while keeping or even improving the mechanical qualities of the finished plastic products. Incorporating PCC into PVC and plastic formulations can enhance mechanical qualities like stiffness, impact resistance, and dimensional stability. This results in the manufacturing of plastic items with increased strength and durability. PCC can improve the surface finish of plastic items by decreasing surface roughness and increasing the overall look.

Use of PCC in the Paint Industry

PCC is used as an opacifying ingredient in paints and coatings to increase opacity and hide power. It improves coverage and colour uniformity on a variety of substrates. PCC acts as an extender in paint compositions, allowing manufacturers to reduce the use of more expensive pigments while preserving desired attributes like color intensity and durability. PCC can improve the rheological qualities of paint formulas, resulting in greater flow, levelling, and brushability. This produces smoother and more consistent paint finishes

Use of PCC in the Rubber Industry

PCC serves as a reinforcing filler in rubber compounds, improving mechanical qualities such as tensile strength, tear resistance, and abrasion resistance. Incorporating PCC into rubber compositions can help cut costs by partially substituting more expensive reinforcing additives such as carbon black or silica. PCC can increase the processability of rubber compounds during mixing, extrusion, and molding, resulting in greater filler dispersion and uniformity in finished rubber products.